Enhancing Industrial Safety with Secondary Network Exhaust Valves: A Comprehensive Guide

2025-04-08

Enhancing Industrial Safety with Secondary Network Exhaust Valves

Table of Contents

Introduction to Secondary Network Exhaust Valves

The Importance of Safety in Industrial Operations

Understanding the Functionality of Secondary Network Exhaust Valves

Types of Secondary Network Exhaust Valves

Key Benefits of Implementing Secondary Network Exhaust Valves

Best Practices f

Enhancing Industrial Safety with Secondary Network Exhaust Valves

Table of Contents

- Introduction to Secondary Network Exhaust Valves

- The Importance of Safety in Industrial Operations

- Understanding the Functionality of Secondary Network Exhaust Valves

- Types of Secondary Network Exhaust Valves

- Key Benefits of Implementing Secondary Network Exhaust Valves

- Best Practices for Installation and Maintenance of Secondary Network Exhaust Valves

- Regulatory Compliance and Safety Standards

- Real-World Case Studies and Success Stories

- Frequently Asked Questions

- Conclusion

Introduction to Secondary Network Exhaust Valves

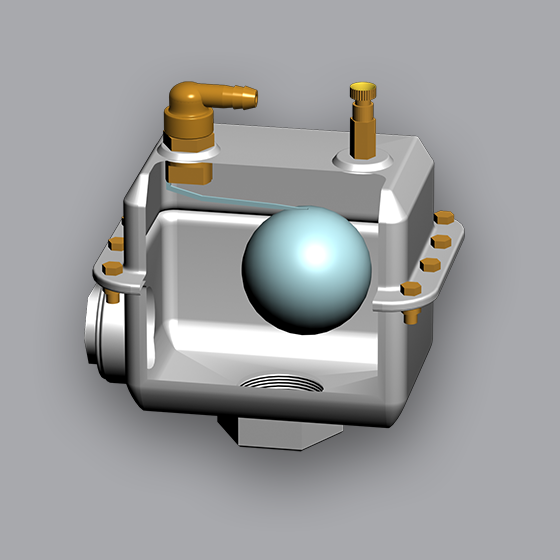

Secondary network exhaust valves play a vital role in industrial safety by managing and controlling the flow of exhaust gases within a facility. These advanced components are designed to enhance the operational efficiency of exhaust systems while minimizing potential hazards associated with gas build-up. As industries continue to adopt stringent safety protocols, understanding the function and benefits of these valves becomes increasingly essential for maintaining a safe working environment.

The Importance of Safety in Industrial Operations

Maintaining a safe industrial environment is not just a regulatory requirement; it's a moral responsibility. Industrial accidents can lead to severe consequences, including injuries, fatalities, and significant financial losses. With increasing regulations and standards in occupational safety, organizations must implement robust systems to mitigate risks. Secondary network exhaust valves serve as a critical line of defense against potential gas-related incidents.

Understanding Industrial Hazards

Industrial settings are susceptible to various hazards, including toxic gas releases, fire outbreaks, and explosions. Implementing secondary network exhaust valves significantly reduces the risk associated with these hazards by efficiently venting harmful gases, ensuring that air quality remains safe for employees.

Understanding the Functionality of Secondary Network Exhaust Valves

At their core, secondary network exhaust valves are designed to control the release of exhaust gases from various industrial processes. The primary function is to maintain optimal pressure levels within the exhaust system, thereby ensuring that harmful gases do not accumulate within the facility.

Mechanism of Action

These valves use advanced technologies such as pressure sensors and actuators to automatically regulate gas flow. When pressure exceeds a predetermined threshold, the valve opens to release excess gas, thereby preventing potential pressure build-up. This automatic response is crucial in maintaining a safe operational environment.

Integration with Monitoring Systems

Modern secondary network exhaust valves can be integrated with comprehensive monitoring systems. These systems provide real-time data on pressure levels, gas concentrations, and valve performance, allowing for proactive maintenance and quick response to any anomalies.

Types of Secondary Network Exhaust Valves

There are several types of secondary network exhaust valves available, each designed to meet specific industrial needs. Understanding these types can help organizations choose the right solution for their operations.

1. Electrically Actuated Valves

These valves are operated via electrical signals, providing quick and accurate control of gas flow. They are ideal for applications requiring precise pressure management.

2. Pneumatically Operated Valves

Pneumatic valves rely on compressed air to operate. These are suitable for environments where electrical sources are limited or where explosion risks must be minimized.

3. Manual Control Valves

While less common in modern applications, manual control valves allow operators to manually regulate gas flow. They are often used in situations where automatic controls are not feasible.

Key Benefits of Implementing Secondary Network Exhaust Valves

Integrating secondary network exhaust valves into industrial operations offers numerous benefits:

1. Enhanced Safety

By effectively managing exhaust gases, these valves significantly reduce the risk of toxic gas exposure, fire, and explosions.

2. Improved Operational Efficiency

Properly functioning exhaust valves ensure optimal pressure levels, which can enhance the overall efficiency of industrial processes.

3. Cost Savings

Investing in secondary network exhaust valves can lead to long-term cost savings by preventing accidents that could lead to property damage, regulatory fines, and increased insurance premiums.

Best Practices for Installation and Maintenance of Secondary Network Exhaust Valves

To ensure the effectiveness of secondary network exhaust valves, adhering to best practices in installation and maintenance is essential.

Installation Guidelines

- **Choose the Right Location:** Position the valves strategically to facilitate optimal airflow and minimize pressure build-up.

- **Follow Manufacturer Specifications:** Adhere to the manufacturer's guidelines for installation to ensure the valve operates correctly.

- **Conduct Thorough Testing:** After installation, conduct a comprehensive testing procedure to verify the valve’s functionality and ensure safety compliance.

Maintenance Best Practices

- **Regular Inspections:** Schedule routine inspections to identify any wear and tear, ensuring valves remain operational.

- **Monitor Performance:** Utilize monitoring systems to track valve performance and detect potential issues early.

- **Train Staff:** Ensure that personnel are trained in the proper operation and maintenance of secondary network exhaust valves.

Regulatory Compliance and Safety Standards

Compliance with industrial safety regulations is paramount. Organizations must stay informed about relevant regulations, such as OSHA standards in the United States or ISO standards globally, that mandate the implementation of safety measures, including the use of secondary network exhaust valves.

The Role of Compliance in Safety

Adhering to safety standards not only protects employees but also enhances a company’s reputation and operational sustainability. Regular audits and compliance checks can help organizations maintain high safety standards and avoid legal repercussions.

Real-World Case Studies and Success Stories

Examining successful implementations of secondary network exhaust valves provides valuable insights into their effectiveness.

Case Study 1: Automotive Manufacturing Plant

An automotive manufacturing facility implemented secondary network exhaust valves to manage exhaust gases from welding operations. As a result, they reported a 30% reduction in air quality violations and improved employee safety ratings.

Case Study 2: Chemical Processing Facility

A chemical processing plant integrated advanced exhaust valves into their operations. This implementation led to a significant decrease in hazardous gas exposure incidents and demonstrated compliance with stringent regulatory requirements.

Frequently Asked Questions

1. What are secondary network exhaust valves?

Secondary network exhaust valves are specialized components that manage and control the flow of exhaust gases in industrial settings, enhancing safety and efficiency.

2. How do secondary network exhaust valves improve safety?

These valves prevent the accumulation of hazardous gases by regulating pressure levels and enabling safe gas venting, thus minimizing the risk of accidents.

3. What types of industries benefit from these valves?

Industries such as automotive, chemical processing, and manufacturing can greatly benefit from implementing secondary network exhaust valves.

4. How often should secondary network exhaust valves be maintained?

Regular inspections should be conducted at least once a year, with performance monitoring systems in place for real-time assessments.

5. Are there specific regulations related to exhaust valves?

Yes, various safety regulations and industry standards govern the use of exhaust systems in industrial operations, including those related to exhaust valve implementation.

Conclusion

The integration of secondary network exhaust valves is a crucial step towards enhancing industrial safety. By understanding their functionality, benefits, and best practices for implementation, organizations can significantly reduce the risks associated with hazardous gas emissions. Investing in these valves not only safeguards employees but also enhances operational efficiency and regulatory compliance. Embracing these technologies is essential for any industry committed to maintaining a safe and productive working environment.

Secondary network exhaust valve

Related information

Unlocking Energy Efficiency: The Role of Floor Heating Exhaust Valves in Modern Industrial Applications

Table of Contents

1. Introduction to Floor Heating Systems and Their Importance

2. What are Floor Heating Exhaust Valves?

3. How Floor Heating Exhaust Valves Enhance Energy Efficiency

3.1 The Mechanism Behind Exhaust Valves

3.2 Benefits of Using Exhaust Valves in Heating Systems

4. K

2025-04-22

Understanding the Importance of Central Heating Exhaust Valves in Industrial Applications

Central heating systems are essential for maintaining optimal temperatures in industrial environments, and the exhaust valve plays a pivotal role in ensuring these systems function efficiently. The central heating exhaust valve is designed to release excess pressure and prevent backflow of gases in heating systems, which can significantly impact performance and safety.

One of the primary functions

2025-04-15

Enhancing Industrial Safety with Secondary Network Exhaust Valves: A Comprehensive Guide

Enhancing Industrial Safety with Secondary Network Exhaust Valves

Table of Contents

Introduction to Secondary Network Exhaust Valves

The Importance of Safety in Industrial Operations

Understanding the Functionality of Secondary Network Exhaust Valves

Types of Secondary Network Exhaust Valves

Key Benefits of Implementing Secondary Network Exhaust Valves

Best Practices f

2025-04-08

English

English Russian

Russian